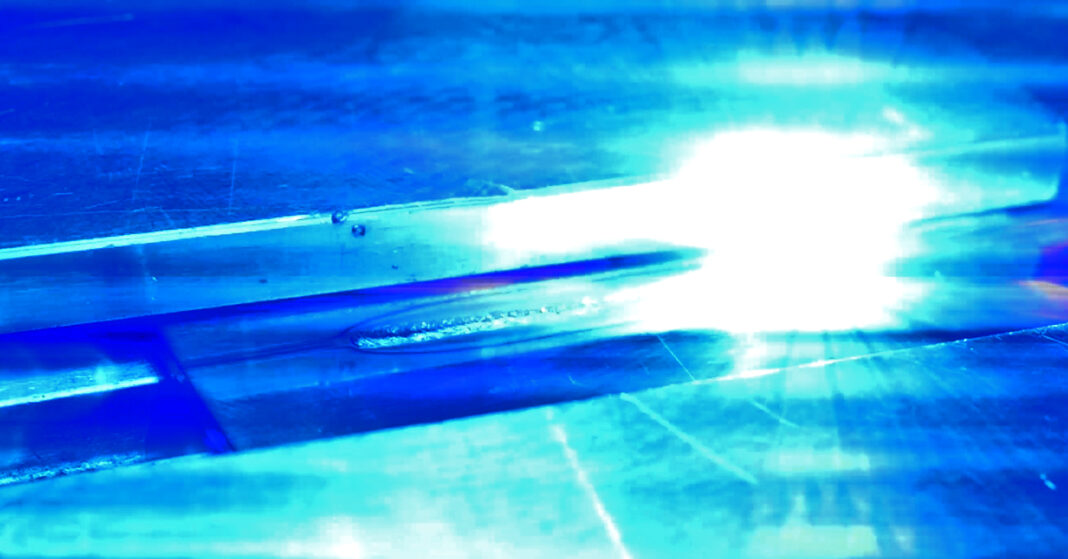

Mülheim-Kärlich, 24.09.2019 – Laserline, the leading international developer and manufacturer of diode lasers for industrial material processing, will exhibit at the Blechexpo / Schweisstec 2019 (5-8 November 2019, Stuttgart, Germany, hall 7, booth 7306) laser systems and processing optics for joining and cladding applications. The highlight will be the presentation of a hybrid solution that connects infrared and blue laser light via a special optic which thus allows for a stable, almost splatter-free keyhole welding of non-ferrous metals. To this end, at the booth, the blue 1.5 kW laser LDMblue 1500-60 and 4 kW infrared laser LDM 4000-100 will be shown. In parallel, possible solutions for controlled heat conduction welding of thin non-ferrous metal components with the LDMblue plus special scanner will also be presented. These two joining concepts were developed in response to the increasing demand for copper as electrical conductor material, as they exploit new manufacturing options for growing markets such as consumer electronics and electromobility.

A further emphasis in Laserline’s presentation is the high-power diode laser LDF 8000-40 that offers on less than one square meter floor space 8 kW output power at 40 mm mrad beam quality. This is especially suitable for welding steel sheets, and is presented together with the OTC-3 S2 optic. The optic is equipped with a sensor package that monitors its condition continuously and thus allows for a decentralized condition monitoring of the most important functional values. This monitoring function is currently being developed by Laserline for all LDF diode laser systems and processing optics which is offered as an optional additional package.

Besides the compact OTC optics for welding and cladding applications, Laserline also displays brazing and welding optics with additional components like crossjets or multi-spot modules for the flexible adjustment of spot geometry and intensity distribution. Furthermore, the range of applications for the diode laser in welding and cladding is underlined by a huge variety of exhibits, amongst them for the first time are laser coated brake disks.