Mülheim-Kärlich, August 14, 2025 – New Blue High Brightness Lasers for the welding of ultra-thin sheet metal structures, along with solutions for implementing more sustainable and efficient manufacturing processes – these are the highlights of Laserline’s presentation at Schweißen & Schneiden 2025 (September 15–19, Messe Essen, booth 5A11). The diode laser specialist will also be presenting a wide selection of its solution portfolio.

Blue Diode Lasers for Copper Welding and Cladding

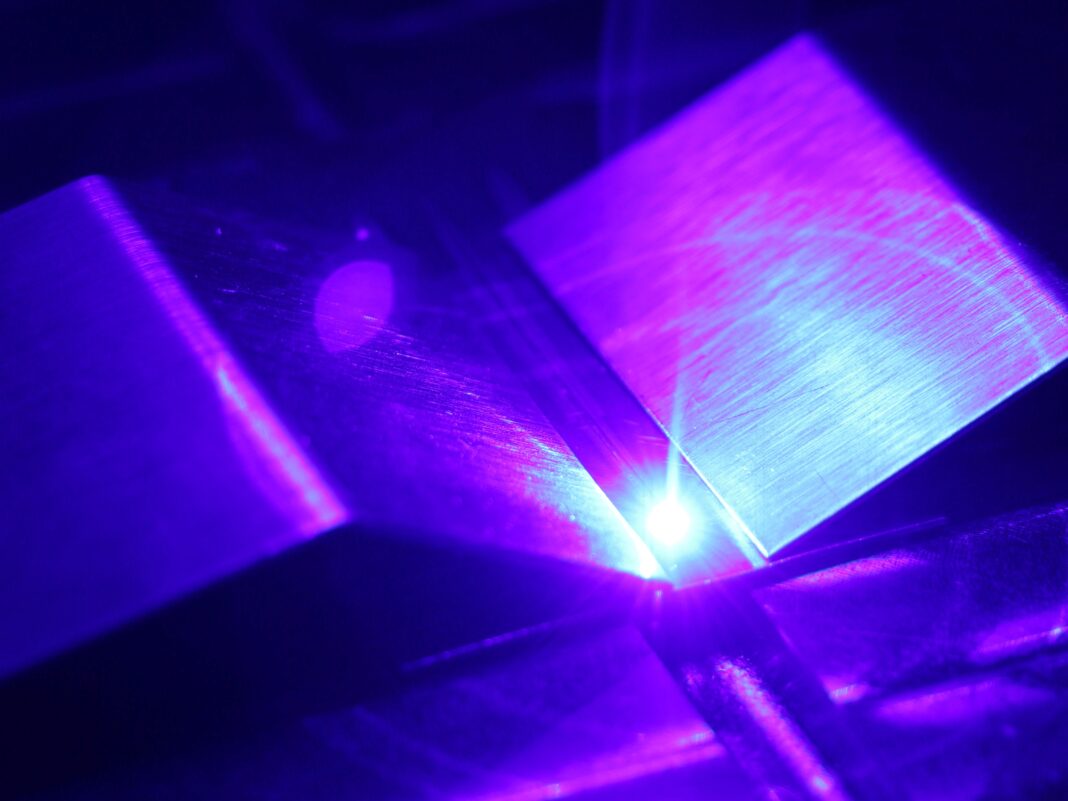

The highlight of the trade fair is the new LDFblue 800-wbc diode laser system, which combines the proven LDF technology with the innovative Blade Engine from WBC Photonics for the first time. The laser offers exceptional beam quality of 4 mm·mrad and is available with output powers of 400 or 800 watts. Thanks to its high brilliance, the system is ideal for spatter-free welding of thin sheets with thicknesses of 100 to 200 µm while maintaining high process stability, which is also ensured by the robust, IoT-enabled system architecture. An LDMblue 1800-30 with blue scanner optics and copper welding samples will also be on display.

Optics for Application-Optimized Beam Shaping

Beam shaping optics will also be part of the trade show presentation. For flexible adaptation to different joining processes, Laserline will present multi-spot optics that enable both beam splitting and individual modulation of spot geometry and intensity. This makes them ideal for demanding welding tasks such as the spatter-free realization of symmetrical and asymmetrical seams with an adapted penetration profile. Laserline will also be presenting special optics for hot wire aluminum welding. This process offers significantly higher process stability compared to conventional methods, reduces heat input into the base material, and enables excellent seam quality at high process speeds. This will be demonstrated by a battery box sample on display at the booth. In the field of thick metal sheet welding, Laserline will showcase the OTS-3 optic along with related exhibits. Thanks to their modular design, these adaptable optics systems are not only suitable for joining processes, but also for heat treatment, cladding, and brazing.

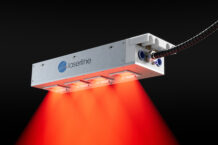

Solutions for Energy-Efficient Surface Treatment

The trade show portfolio also includes systems for industrial surface treatment such as heat treatment, curing of paints, powder and polymer coatings, and cladding. For example, the diode laser specialist will present energy-efficient solutions for the environmentally friendly serial coating of brake discs. At the center of this is the 30 kW diode laser, which enables significantly shorter process times thanks to its high output power. Particularly noteworthy is the option of double-sided coating, in which both sides of the brake disc are processed simultaneously. This leads to more uniform heating of the workpiece and reduces the risk of deformation.

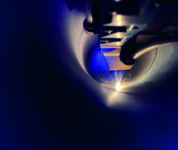

New APF Process Fiber for Highly Focused High-Power Applications

Visitors to the booth can also learn about the new Active Process Fiber (APF). This powerful hybrid solution for demanding industrial applications is particularly suitable for processes such as cutting, remote welding, cladding, and heat treatment, which require a very small focus and high laser power. With its combination of a high-power diode laser source and two standard beam outputs, the system enables flexible, application-specific switching between a standard process fiber and the APF – without the need for additional laser systems. The APF offers high brilliance at output powers of up to 6,000 W and is available with fiber core diameters of 50 μm and 75 μm. For applications requiring higher power, a 1,000 μm standard fiber is available, enabling output powers of over 20 kW. The hybrid configuration offers a flexible and efficient solution for a wide range of application scenarios – from fine material processing to large-area surface treatment.