Mülheim-Kärlich, October 2, 2025 – Special optics for laser cladding are the focus of Laserline’s presentation at this year’s formnext (November 18 to 21, Frankfurt am Main, Hall 12.0, Booth C122). The highlight of the trade show is the newly developed OTZ zoom optics for diode lasers with up to 30 kW output power. Laserline zoom optics have already set standards in the flexible cladding of components, and the new 30 kW version now marks another milestone in the continuous development of high-performance cladding solutions. It allows variable adjustment of the spot size and is therefore ideal for a wide range of process requirements – from the processing of small precision components to large surfaces. This makes it ideal for applications involving frequently changing workpieces, such as those found in contract manufacturing. A model of an OTZ optic will be on display at the booth.

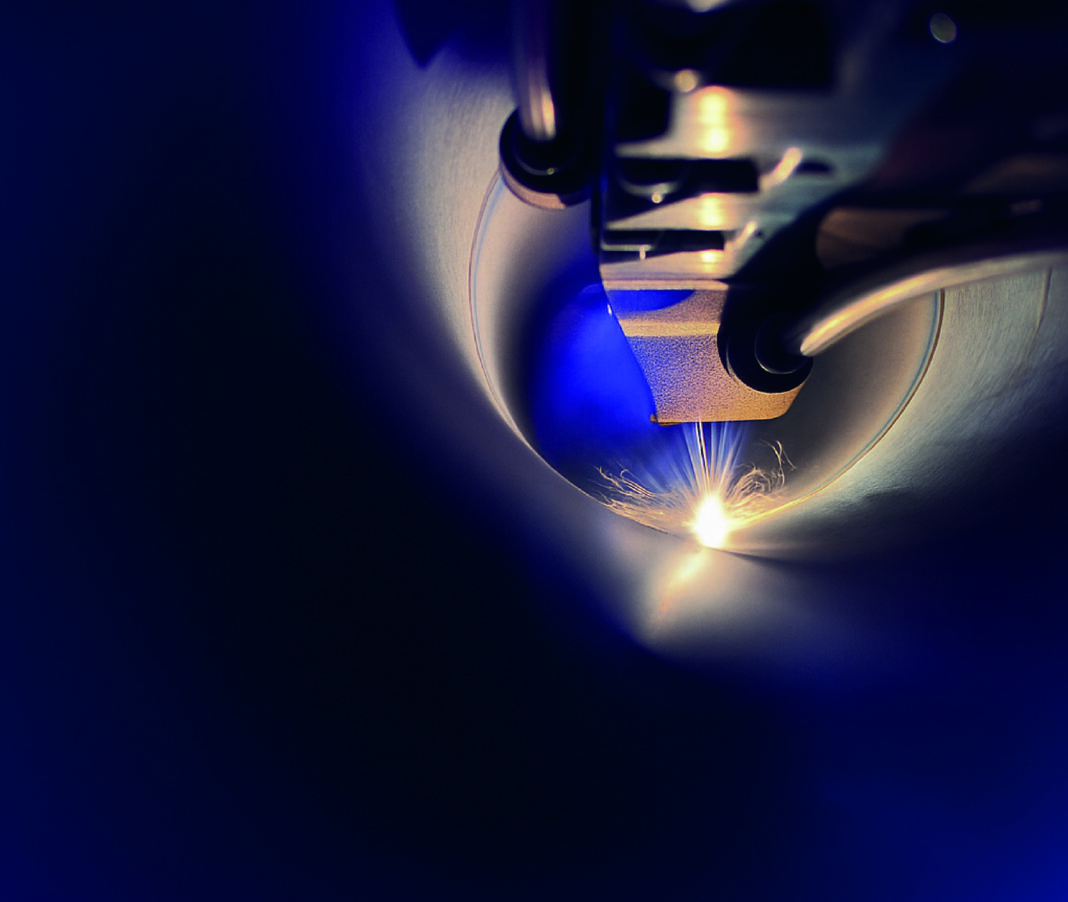

Internal Cladding of Pipes and Truck Brake Discs

The new OTI optics are also part of the trade show portfolio. They were specially developed for the implementation of corrosion and wear protection coatings on cylindrical and linear internal geometries such as pipes and complex components such as truck brake discs. Due to their geometric properties, coating these components is particularly challenging. Nevertheless, the OTI optics enable reliable processing even in areas that are difficult to reach. Its compact design and angled nozzle allow for large immersion depths of up to several meters and ensure precise laser beam guidance along the pipe axis. The result: homogeneous coating over the entire length of the component with high reproducibility. In combination with the powerful Laserline diode lasers, the optics enable high material deposition rates and process speeds, even on larger internal surfaces. Thanks to their compact design, the new OTI optics can also be easily integrated into automated manufacturing processes. Visitors to the Laserline booth are welcome to learn more about the advantages of this solution.

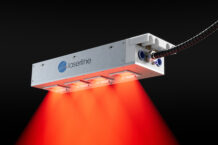

Additive Manufacturing of Copper Components Using High Brightness Laser

In addition, Laserline showcases two blue high brightness diode lasers at formnext: the LDFblue 400-wbc and the LDFblue 800-wbc, which combine the industry-proven LDFblue technology with the innovative blade engine from Laserline’s subsidiary WBC Photonics. They operate at a wavelength of 445 nm and, thanks to their excellent absorption in non-ferrous metals, enable highly material-efficient, spatter-free additive manufacturing of copper, gold, or aluminum components in the laser-based powder bed process (laser powder bed fusion). The high brightness lasers are available with output powers of 400 or 800 watts and fiber diameters of 50 µm or 100 µm. Their robust, IoT-enabled system architecture ensures high process stability and facilitates integration into modern manufacturing environments.

Further information about Laserline and the products presented can be found at https://www.laserline.com/