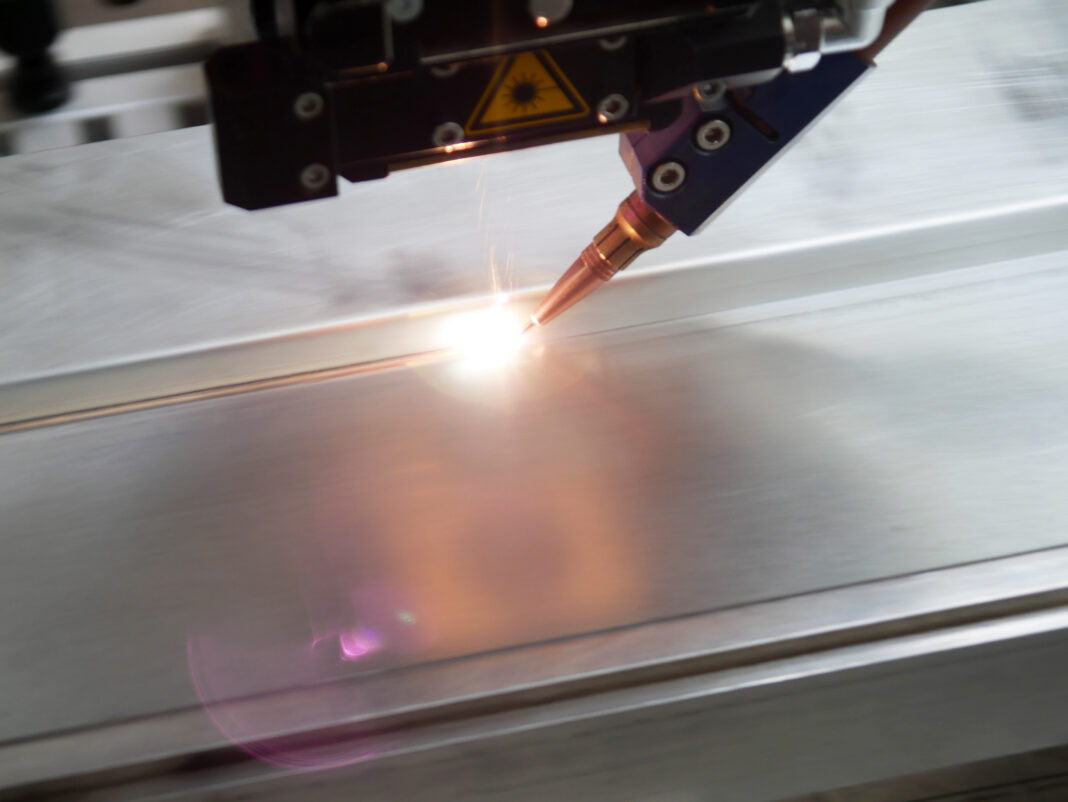

Mülheim-Kärlich, 27.04.2018 – Laserline, the leading international developer and manufacturer of diode lasers for industrial material processing, will exhibit at the LASYS 2018 fair (5th to 7th June 2018, Stuttgart, Germany, hall 4, booth 4B53) compact laser systems for cladding and joining applications as well as heat treatments. A key highlight of the fair presentation will be the fiber-coupled LDF 6000-6 diode laser with beam converter. It combines high output power (6 kW) with high brilliance (6 mm∙mrad beam quality), and is therefore suitable specifically for applications with above average precision requirements such as remote welding. Furthermore, from the Laserline LDF series, the LDF 5000-30 with 5 kW output power and 30 mm∙mrad beam quality will be presented — a classical high-power diode laser for typical welding and brazing applications that can be used even beyond the automotive sector.

Besides its LDF systems, Laserline will exhibit at the LASYS 2018 the LDM 6000-100 diode laser module that is mainly used for cladding applications and heat treatments. Designed as a 19″ rack mount, it offers with a size of only 7 height units up to 6 kW power and thus sets a new standard for compact high-power diode lasers. Also on board is the blue diode laser LDMblue with a 450nm wavelength, which offers output powers of up to 700 W. With this system, which was developed in close collaboration with OSRAM and other project partners within the EFFILAS support measure of the Federal Ministry for Education and Research (BMBF), it was possible to reliably carry out diode laser-based heat conduction welding of highly reflecting metals process. With conventional infrared laser beam sources, this has not been possible — until now. The trend towards blue diode lasers is, besides other factors, driven by the development of new manufacturing technologies in the electrical contact area, e.g. in battery and rechargeable battery production for the growing field of electromobility.

In addition to the diode laser systems, special Laserline processing optics such as the OTS-5 brazing and welding optic with multi-spot module and the OTS-5 cladding optic with Coax 11 broad beam nozzle will also be on display at the booth. The fair presentation will be rounded off by showcasing different components from the application areas of welding, brazing, hardening, cladding, and additive manufacturing.